Several of our workstations now feature the HK Smart Cell and Smart Tower Auto-loading Systems, pivotal in managing high-volume tasks demanding precision and repeatability. With these systems in place, our clients enjoy expedited turnaround times and reduced production costs, as the automated processes minimize the need for repetitive quality checks and manual interventions.

The integration of HK Systems AGV further amplifies our efficiency, with these automated guided vehicles seamlessly ferrying materials between production stages, eliminating the need for human intervention and streamlining our operations.

Our unwavering commitment to safety and precision is evident in our adoption of Cranesmart Load Cell technology.

Critical to our operations are the components supplied by Load Cell Automation Direct. Analytics Their dependable load cells play a vital role in weighing and batching processes, guaranteeing accuracy and consistency in production.

The integration of Smart Load Cells has unlocked a higher tier of data precision, empowering automated decisions that fine-tune production workflows and elevate product quality. Similarly, the utilization of 6-axis Load Cells delivers crucial multi-directional force and torque measurements, indispensable for intricate assembly tasks.

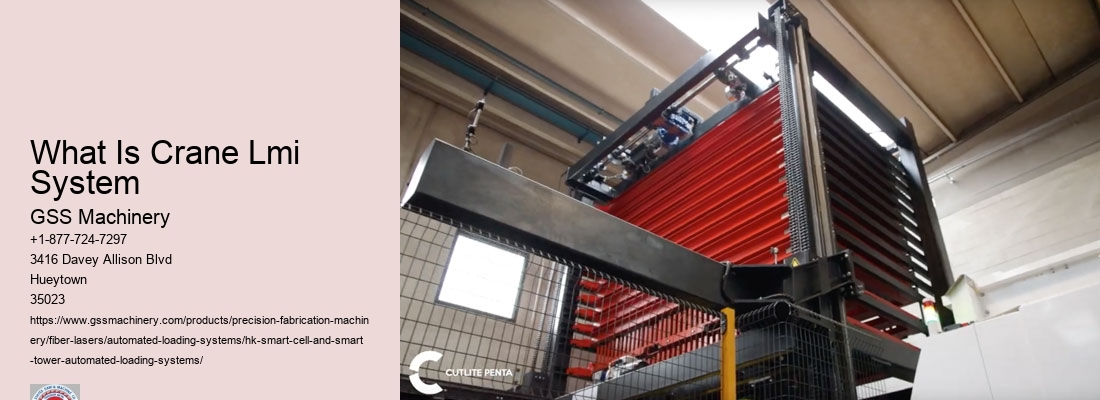

At Gulf States Saw & Machine Co., we're proud to be pioneers in industrial innovation, embracing state-of-the-art solutions like the HK Smart Cell and Smart Tower Automated Loading Systems.

The seamless integration of HK Smart Cell and Smart Tower Automated Loading Systems has completely revamped our approach to logistics and inventory management. Stacking By embracing this innovation, we've significantly reduced manual errors and supercharged the efficiency of our warehouse operations. The Smart Tower Automated Loading Systems, in particular, excel in facilitating smooth loading and unloading operations, ensuring a seamless flow of activities.

By leveraging the HK Smart Cell & Smart Tower Automated Loading Systems, we've optimized space utilization and enhanced the precision of our loading tasks.

At the heart of this technology lies the HK Smart Cell with Smart Tower Automated Loading Technology, boasting advanced sensors and software that orchestrate tasks autonomously, previously reliant on manual labor. This not only saves time but also significantly mitigates workplace safety risks.

Several of our workstations now boast the HK Smart Cell and Smart Tower Auto-loading Systems, playing a crucial role in managing high-volume tasks demanding precision and repeatability. Management With these systems in place, our clients experience expedited turnaround times and reduced production costs, as the automated processes minimize the need for repetitive quality checks and manual interventions.

The integration of HK Systems AGV further amplifies our efficiency, with these automated guided vehicles seamlessly ferrying materials between production stages, eliminating the need for human intervention and streamlining our operations.

Our unwavering commitment to safety and precision is evident in our adoption of Cranesmart Load Cell technology. Manufacturing These devices ensure that loads are meticulously managed, preventing overloads and potential accidents. Similarly, the JR Automation Tote Stacker systems optimize storage solutions, maximizing vertical space and enhancing facility organization.

MaterialsCritical to our operations are the components supplied by Load Cell Automation Direct.

The integration of Smart Load Cells has unlocked a higher tier of data precision, empowering automated decisions that fine-tune production workflows and elevate product quality. Similarly, the utilization of 6-axis Load Cells delivers crucial multi-directional force and torque measurements, indispensable for intricate assembly tasks.

At Gulf States Saw & Machine Co., we take pride in our commitment to cutting-edge industrial solutions, exemplified by our adoption of the HK Smart Cell and Smart Tower Automated Loading Systems. These innovations stand as testament to our dedication to pushing the boundaries of efficiency and safety across diverse sectors.

The seamless integration of the HK Smart Cell and Smart Tower Automated Loading Systems has revolutionized our logistics and inventory management practices. Retrieval Embracing this advanced technology has not only minimized manual errors but also turbocharged the efficiency of our warehouse operations. Particularly noteworthy is the Smart Tower Automated Loading Systems' ability to streamline loading and unloading processes, ensuring a seamless workflow.

Through the utilization of the HK Smart Cell & Smart Tower Automated Loading Systems, we've optimized space utilization and elevated the precision of our loading tasks. This intelligent system adapts to its operational environment, constantly refining its efficiency to meet evolving demands.

At the core of this innovation lies the HK Smart Cell with Smart Tower Automated Loading Technology, boasting sophisticated sensors and software that autonomously manage tasks previously reliant on manual labor. This not only saves time but also enhances workplace safety by minimizing risks.

Numerous workstations across our facility now feature the HK Smart Cell and Smart Tower Auto-loading Systems, playing a pivotal role in managing high-volume tasks with precision and repeatability. With these systems in place, our clients benefit from expedited turnaround times and reduced production costs, thanks to minimized need for quality checks and manual interventions.

The integration of HK Systems AGV further enhances our operational efficiency, with automated guided vehicles seamlessly transporting materials between production stages without human intervention.

Our steadfast commitment to safety and precision is underscored by our use of Cranesmart Load Cell technology. These devices ensure meticulous load management, preventing overloads and potential accidents. Similarly, the JR Automation Tote Stacker systems optimize storage solutions, maximizing vertical space and enhancing facility organization.

Smart Tower Automated Loading Systems improve efficiency by reducing the time and labor required for loading and unloading goods, enhancing precision, and minimizing errors, which is crucial in high-volume logistics environments.

HK Smart Cell and Smart Tower Automated Loading Systems are integrated automation solutions designed to optimize the efficiency of material handling and storage operations by leveraging advanced robotics and intelligent software systems.

OSI Smart Grid technology introduces innovations in energy management by enabling more efficient transmission of electricity, better integration of renewable energy sources, and enhanced monitoring and control of the grid.

JR Automation's Tote Stacker enhances warehouse operations by automating the stacking and storage of totes, reducing manual handling, and increasing storage density and retrieval speeds.